Pneumatic tin machine

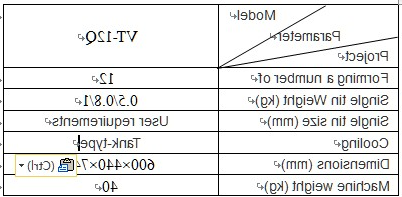

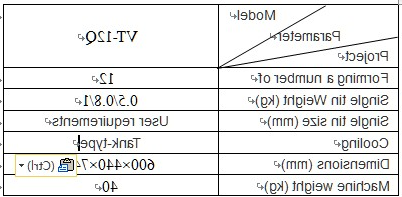

1.Technical parameters:

2. Device description:

This equipment is mainly used for hand pouring tin, tin melting furnace has been melted tin tin of water pouring into the mold until the mold tin tin removed after solidification by cooling water. Pneumatic tin machine is simple, maintenance side to make.The machine consists of frame, mold, from the model device composed of a cooling water tank underneath the template, the mold is cooled, to increase production and to improve the surface quality of tin.Casting mold using a dedicated tool (tin pot), after the melting of tin is poured into molds, wait tin water after curing in the mold to cool, using pneumatic jacking thimble, remove the tin. Scope: For a lead-free solder bar casting.

3. Features:

1 mold made of high strength tool steel, to ensure that mold durable, tin smooth surface, small deformation.

2 high production efficiency: tin cooling rate is rapid, uniform cooling.

3 easy to operate, using pneumatic from mold, machine, compact structure, easy maintenance.