Automatic hemisphere machine

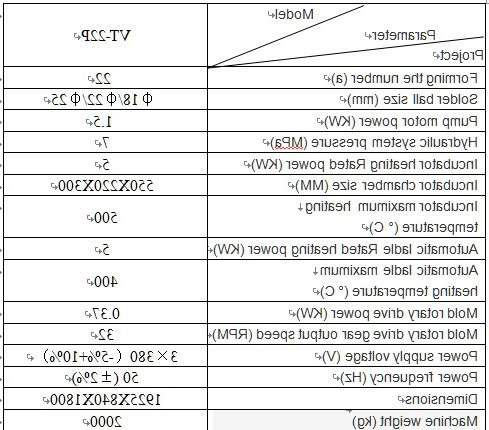

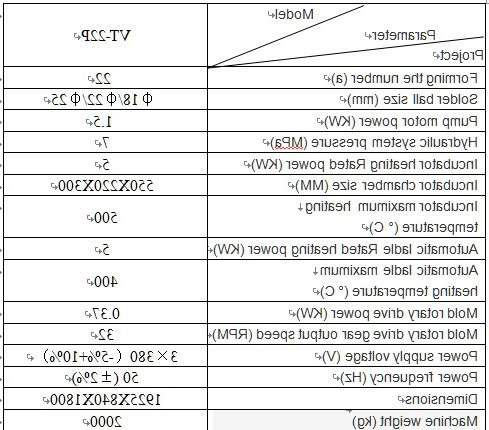

1.Technical parameters:

2.Equipment Description:

Automatic hemisphere at the top of the machine consists of electrically heated incubator liquid tin, tin cylinder driven valve, cylinder drive electric heating insulation controlled automatic ladle, motor-driven auto-rotating eight rotary chute hemisphere mold and other components. For tin, lead and their alloys hemisphere strip casting.

Incubator for storing molten metals and automatically control the temperature to process requirements. Mining A3 steel welded cabinet insulation, liner made of stainless steel welded pipe using an electric heating.

Incubator with automatic tin cylinder drive cone sealing valve. When the automatic ladle back flat position, the bag tin fluid level is below the liquid level gauge set, the control valve to open tin, tin-lead solder solution through its pipe into the bottom of the ladle automatically. Tin ladle liquid level reaches the upper limit level meter set to automatically turn off tin liquid valve.

Automatic ladle for the whole piece thick steel plate produced by precision machining to make pouring nozzle 22 in the same plane, to ensure a casting 22 hemispheres the size and weight accuracy requirements; auto ladle with electric heating and temperature control system in order to control the pouring temperature, pouring nozzle clogging prevention purposes. Automatic ladle pouring automatically driven by a cylinder, i.e., when the package reaches the liquid surface level of tin, 8 translocation to be hemispherical mold casting position, the control system makes operation of drive cylinder casting ladle pouring embodiment, the ladle Through its 22 rotating nozzle pouring pouring molten tin at its inner hemisphere corresponding mold cavity 22 hemisphere.

By the rotation angle of the automatic ladle pouring stopper tin amount to achieve the precise control.

Automatic swing 8 hemisphere mold using hot work die steel overall manufacture. Circumferential direction as 8 can be used for two or four kinds of specifications; each axial grooves 22 are arranged with the automatic pouring ladle nozzle 22 corresponds, namely to achieve an automatic pouring 22 products. Left and right ends of the mold by the cooling water through the rotary valve into the eight rotary mold, the casting and mold cooling to speed up, to increase productivity purposes. 8 hemispherical mold by the motor via reducer and friction clutch driven to rotate, the circumferential positioning a positioning block and cylinder positioning, that cylinder piston rod, mounted on the positioning of the mold block spray to the piston rod, the friction clutch slipping, mold Turn rotary blocked achieve positioning. When the automatic pouring completed and casting cooling reaches the set time, the system automatically controls the cylinder rod is retracted, the friction clutch friction driven rotary die. A casting mold cavity go downward, the gravity and the centrifugal casting in the mold cavity under the action of prolapse. At the same time and location of the cylinder block joint action to achieve circumferential positioning of the mold, go to the upper position to implement automatic pouring cavity, so the cycle can achieve automatic hemisphere Casting.

Extrusion casting of the mold cavity below the collecting chute in the container.

Scope: For lead, lead-free solder ball casting half.

3. Features

1. High production efficiency, yield: the machine is able to automatically and continuously work to reduce the use of hand-cast tin water install take workload and efficient effort.

2. Measurement precision, weight control: Metering is controlled by a solenoid valve actuator movement can be accurately controlled tin tin pot pour water time.

3. Easy to operate, safe and reliable: tin water pouring control system is done automatically, without casting such as manual labor intensity, simply operate on the control panel can be easily completed. Water is a hot tin items, hand-cast in the operating personnel is often easy to burn, cast by machine, you can avoid this from happening.

4 can produce two kinds or four kinds of product specifications, simple adjustment.